As industries continue to demand faster, more accurate data collection, laser scanning is emerging as a transformative solution. By using focused laser beams to capture precise geometric details, this technology provides engineers and planners with rich, actionable information.

- Laser Scanning in Modern Engineering: A Versatile Tool for Accurate Data Collection

- How Laser Scanning Works

- Key Applications in Industry

- Benefits and Challenges of Laser Scanning

From construction sites to heritage preservation, laser scanners are changing how we document, analyze, and manage the physical world.

Laser Scanning in Modern Engineering: A Versatile Tool for Accurate Data Collection

Laser scanning has become an essential technique in modern engineering, construction, and preservation work. This advanced technology uses laser beams to measure objects, distances, and surfaces with high precision, providing valuable point cloud data for many applications. From reverse engineering to heritage documentation, laser scanners are changing the way industries capture, measure, and analyze the built environment. Unlike traditional tools such as total stations, 3D laser scanning can offer faster, more accurate results while reducing the time-consuming stages of manual surveying. Whether it’s for planning, maintenance, or complex geometry documentation, laser scanning is proving to be the ideal tool for civil engineers, architects, and specialists alike.

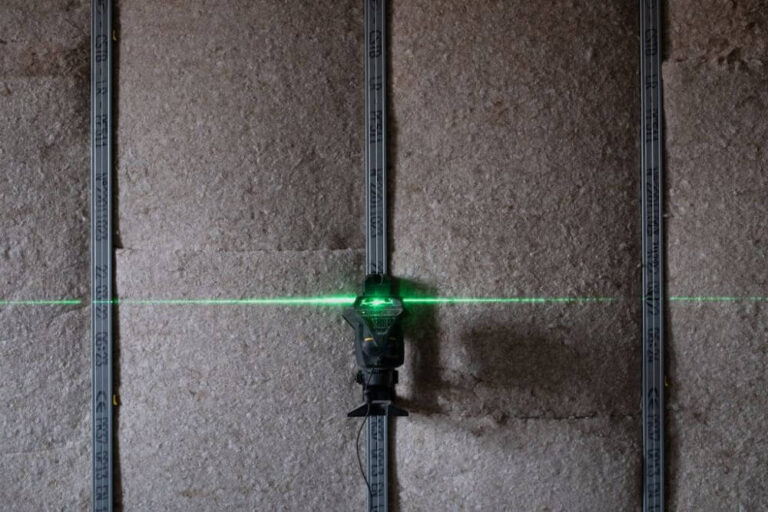

How Laser Scanning Works

Laser scanning works by directing a focused laser light at a surface. The scanner detects the reflected beam to calculate distance, creating a dense cloud of data points known as a point cloud. This collection of points captures the shape and geometry of an object or space, which can then be imported into specialized software for further analysis, modeling, or visualization. Technologies like galvanometer scanners, polygon mirrors, and confocal microscopy help improve scanning speed, detail, and resolution depending on the system in use. The intensity and timing of the reflected laser beam provide insights not only into shape but also surface texture and material reflectivity.

Key Applications in Industry

The use of laser scanning services spans across engineering, construction, architecture, and heritage preservation. In the construction phase, scanning helps with project management, real-time documentation, and quality control. In reverse engineering, laser scanners are used to measure existing parts or objects and replicate them with digital accuracy. Civil engineers utilize scanning for infrastructure monitoring, road planning, and bridge inspections, gaining actionable insights into wear, deformation, or alignment shifts. Preservation experts scan historical buildings and artifacts to create digital archives, aiding in restoration and long-term maintenance.

Laser scanning technology plays a key role in creating a digital twin, allowing engineers to generate precise virtual replicas of physical assets for analysis, monitoring, and simulation.

Benefits and Challenges of Laser Scanning

Laser scanning offers numerous benefits, including non-contact measurement, high accuracy, and rapid data collection. It allows experts to access hard-to-reach areas, reducing the need for moving parts or scaffolding. However, the technology also has its challenges. Scanning in poor lighting or reflective environments can produce noise in the data, and the initial investment in equipment and training may be high. Despite this, scanners remain one of the most versatile and essential tools in surveying and automation processes today.